Companies need an integrated supply chain to increase competition in the globalized marketplace. There are many links in a firm, from the suppliers to the final customers. It is possible to bring all these parties together with supply chain integration and even save time and money. However, what exactly is a supply chain and supply chain integration? What impact does supply chain integration have on performance? Keep reading to discover more about these.

Supply Chain and Supply Chain Integration; What Are They?

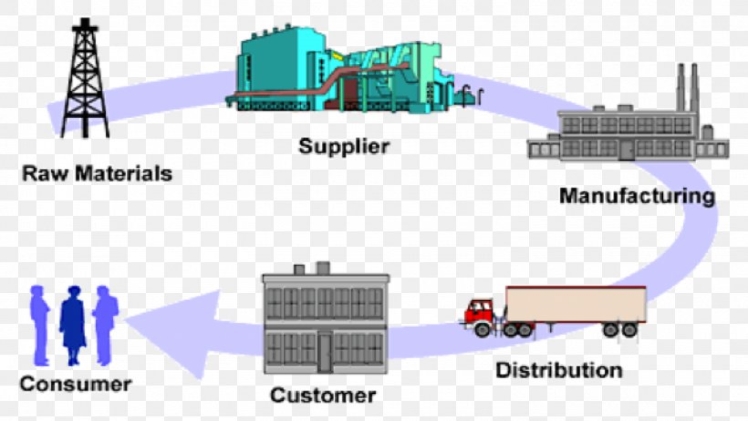

Before you discover more on what impact an integrated supply chain has on performance, how about you first know what a supply chain and supply chain integration are? A supply chain is the collection of all the inputs a company requires to produce a particular product or fulfill a purchase. The link in this chain is the supplier, and his inclusion means additional costs in terms of time and money. To fulfill a purchase, the parties involved in a supply chain range from the raw materials, how they are manufactured into a product, transportation of the completed item to supporting numerous services offered by a company.

On the other hand, supply chain integration is the strategy businesses use on a large scale to bring together all the links of a supply chain so that there is a close working relationship created among the parties involved. Thanks to this strategy, a company can save on time, from how fast the production takes place to the response rate. Therefore, it brings an aspect of coordination. Moreover, supply chain integration makes it possible for a company to reduce costs and waste.

Significantly, every link in a supply chain should benefit from the strategy. There are different ways through which supply chain integration can be achieved. For instance, a firm can merge with another or even communicate with suppliers and customers in a bid to share information. A company can do all these to have a competitive advantage in the market.

One advantage of supply chain integration is the ability to know costs. This is possible because a company has a particular supplier for a specific material or product. From such, a contract can develop, and, therefore, it is easy to come up with a set price for an item. With a fixed cost, a company can thus come up with a selling price for the product as it gets the needed profit.

The Impact of Supply Chain Integration on Performance

Many organizations use supply chain integration as a strategy to align their functions and processes. However, determining the specific approach or design that leads to the performance of the supply chain may not be easy. Also, there is a lot of competition in the industry. Hence, the need to remain relevant despite the numerous evolution.

The following are some of the impacts of supply chain integration on supply chain performance;

Improved Product Quality

Supply chain integration makes it easy for a firm to conduct internal and external communication with the parties involved in the process of producing a product and fulfilling a purchase. With this strategy, they can be more efficient in the process. It will share a lot of information necessary to have quality products.

Also, with a particular supplier in charge of a specific product, it is easier to ensure the quality of the product is maintained. Nonetheless, determining the selling price becomes easier with such contracts. Since the industry is very competitive, a firm will strive to ensure it offers only the best services and products to the consumer, so they don’t have a reason to search for them from a competitor. One way of achieving this is by prioritizing quality.

Organizations Gaining Competitive Advantage

With supply chain integration, firms and organizations are formulating strategies to counter competition and focus more on what can bring change. In the current global economies, there is stiff competition among firms; hence, a company must shift its strategies to gain an advantage.

When a company or firm has an integrated supply chain, it can form partnerships with other firms, a move that places it ahead of its competitors in the large marketplace. Moreover, doing this can help save time and build closer relationships among other links in a supply chain.

Timely Delivery of Orders

When a firm or company’s supply chain is integrated, the parties involved in the supply chain are interrelated; from the suppliers to the manufacturers, so that the end consumer can get the products and services on time and be satisfied. When this happens, a customer does not have to go to your competitor to get an item. Also, when a company partner with others, saving time in the processes.

Improved Financial Performance

This is one of the benefits a firm’s supply chain can realize from integrating the supply chain. Therefore, supply chain managers should take advantage of this strategy to boost their profitability and financial figures. This is possible through the relationships formed through the various links of the supply chain.

Remember, with proper communication among members of a supply chain; they can easily adjust to changes in the marketplace. This makes them flexible to any changes, whether short or long-term. Also, parties in the supply chain can look for various ways of reducing costs.

Improved Internal and External Coordination

The links in a supply chain involve the supplier, manufacturer, raw materials, and customer. There are other internal processes of the firm which are improved by supply chain integration. Remember, this strategy makes it easy for parties to communicate since information is easily shared. Therefore, there is a lot of coordination within the external and internal environment of a firm.

Moreover, when there is internal coordination, there is a reduction in costs in the supply chain. The firm can also improve its internal efficiency to ensure that consumer satisfaction is guaranteed.

Read more here cloudvents.net

Conclusion

A firm needs an integrated supply chain to survive in the competitive marketplace. The good thing is that this strategy brings all the links of a supply chain together. Thus, with proper and close communication, the supply chain performance will benefit. For instance, the impact can be improved financial performance, improved quality products, and enhanced internal and external coordination. Therefore, every firm should integrate its supply chain.

Read more here nethunts.net